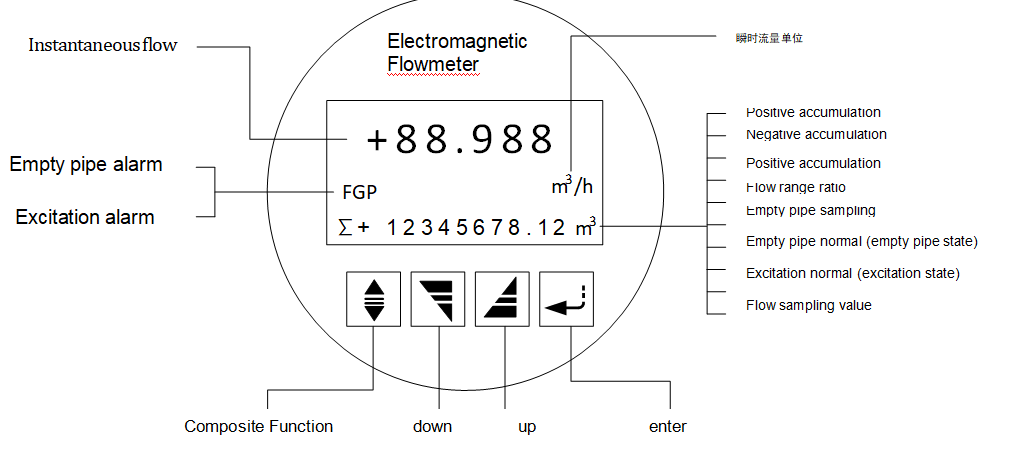

Integrated electromagnetic flowmeter

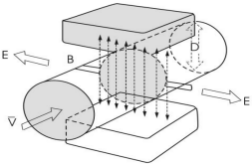

The working principle of electromagnetic flowmeter is based on Faraday's law of electromagnetic induction. Electromagnetic flow meters are widely used in various industries due to their advantages of low pressure loss, wide applicability to various media, and large measurable flow range. Electromagnetic flow meters are widely used in production processes such as sewage treatment plants (environmental wastewater control, chemical wastewater, electroplating wastewater), steel metallurgy, water supply and drainage, water conservancy irrigation, tap water treatment, mud pulp, medicine and food.

This protocol complies with the MODBUS-RTU communication regulations and is transmitted in hexadecimal

Serial port collocation: 8 data bits, 1 stop bit, no check.

Port rate: 2400bp s (tacit recognition), 4800, 9600, 19200

The interval between reading data is better than 500ms or the bit error rate will increase

Model : | Water Flow Meter |

Place of Origin : | China |

DeliveryTime : | 7-10 working days |

MOQ : | 1 PCS |

Pay : | TT,LC |

Customized support : | OEM, ODM, OBM, Software reengineering |

Measuring range : | 4.0MPa |

Type : | Electromagnetic Flow Meter |

Warranty : | 1 year |

Accuracy : | ±0.5%R,±1%R |

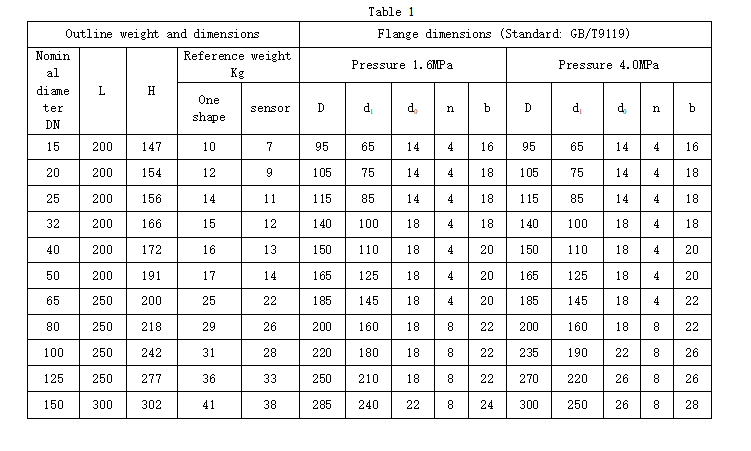

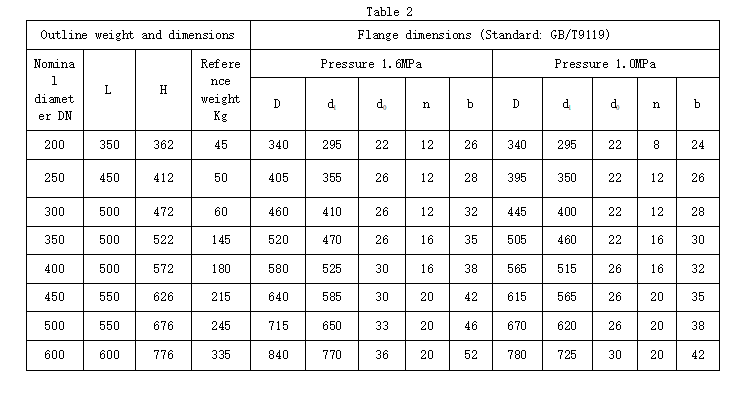

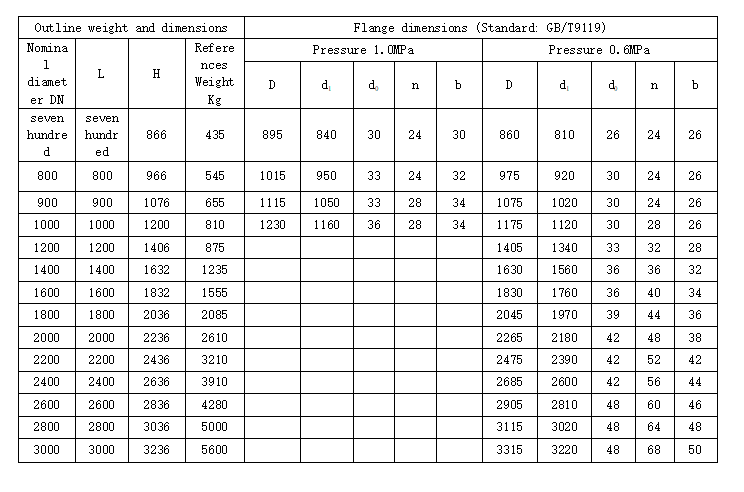

Range standard : | DN15-DN3000 |

Protection grade : | IP65 , IP68 |

Lining material : | PTFE Lined /Polyurethane/JPEFE/F46 (Optional ) |

Application : | Water & Wastewater Treatment |

Power Supply : | 110/220VAC (100-240VAC), 50Hz/60Hz; 24VDC±10% |

Output signal : | Pulse / 4~20mA / RS485 |

Thread : | 15m/s |

The working principle of electromagnetic flowmeter is based on Faraday's law of electromagnetic induction. In Figure , the two electromagnetic coils at the upper and lower ends produce a constant or alternating magnetic field. When the conductive medium flows through the electromagnetic flow rate, the induced electromotive force can be detected between the left and right electrodes on the wall of the flowmeter. The induced electromotive force is proportional to the velocity of the conductive medium, the magnetic induction intensity of the magnetic field, and the width of the conductor (the inner diameter of the flowmeter measuring tube). Then through the calculation you can get the flow of the medium.

Step Description

Characteristic

Sensor installation process

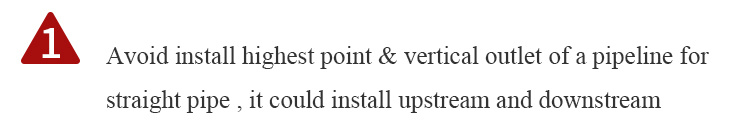

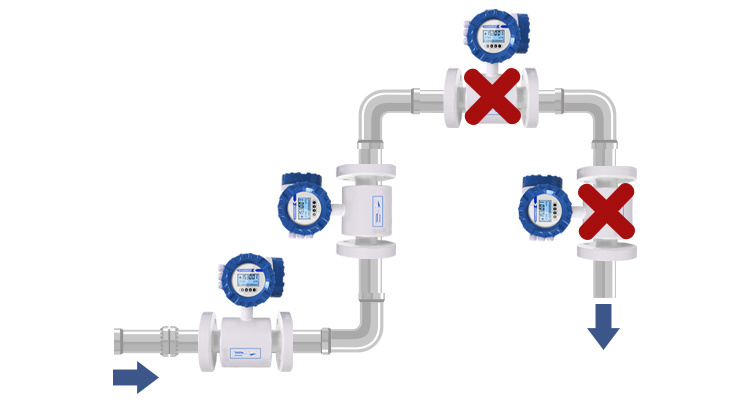

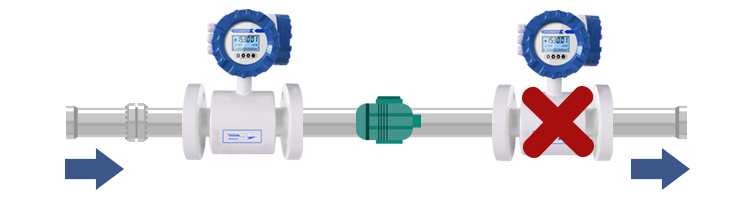

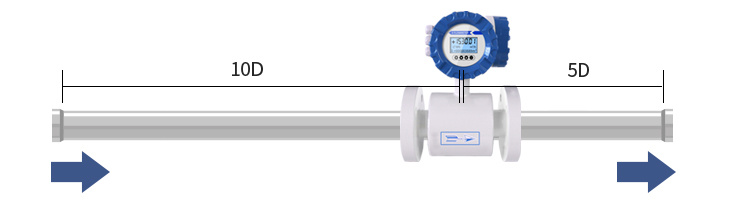

Horizontal and vertical flow direction, electromagnetic flowmeter should be installed in the horizontal pipe at the lower and vertical upward, to avoid installation in the pipeline at the highest point and vertical down

Inclined flow direction, the electromagnetic flowmeter should be installed in the pipeline rise

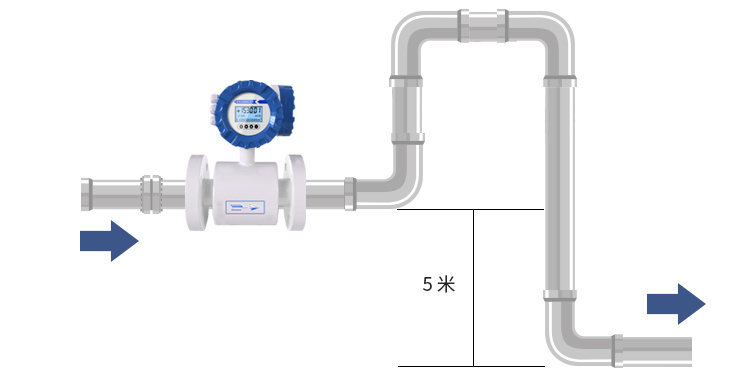

In the open discharge pipe, the electromagnetic flowmeter should be installed in the lower part of the pipeline

If the pipe drop exceeds 5m, the exhaust valve should be installed in the downstream of the electromagnetic flowmeter

Downstream of the electromagnetic flowmeter, and should not be installed in the upstream of the sensor

Electromagnetic flowmeter must not be installed at the pump inlet and outlet, should be installed at the pump outlet

Keywords:

YTLL(Integrated&Split electromagnetic flowmeter)

Related Downloads

YTLL(Integrated&Split electromagnetic flowmeter)

Contact Us